Since affordable commercial 3D printers hit the market, we also joined that ever growing community, so we started out with very simple 3D Designing programs.

However since the designs we made for specific niche products where more complex a more professional program became necessary, so for our demands Fusion 360 from Autodesk forfilled our needs.

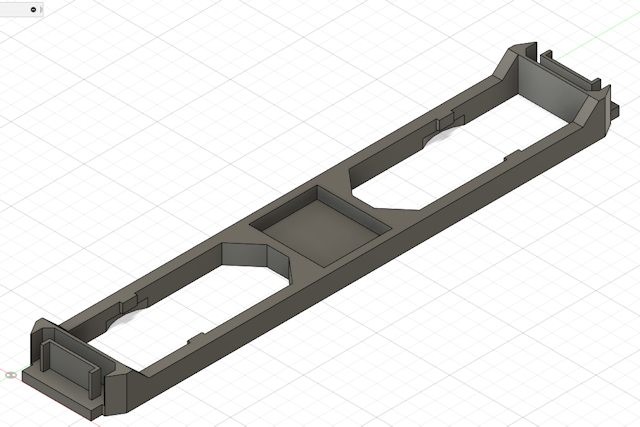

The first design we made was an internal chassis of a HO scale model train that was originally manufactured in zamak, but suffered zamak rot which is a destructive, inter-crystalline corrosion process of zinc alloys containing lead impurities. The chassis cracks, expands and finally the plastic body of the locomotive literally cracks open…

This is the final design created with Fusion 360 that went into production a few years ago.

The original chassis in zamak is no longer manufactured since decades, so we sold about a dozen of these 3D printed models so far…

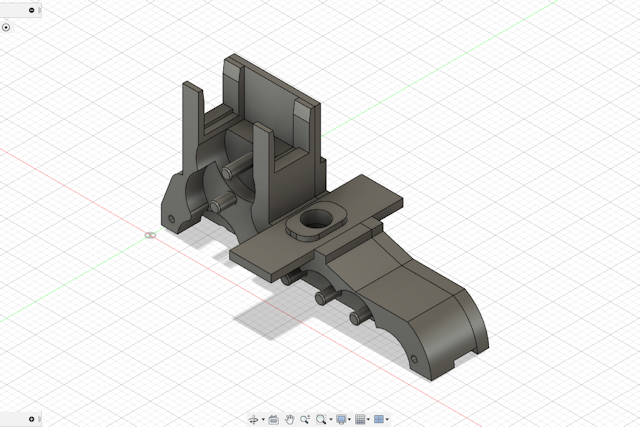

This design is a bogie of a ROCO HO Scale locomotive that suffered the same ZAMAC rot problem, but is no longer manufactured by ROCO.

Some minor detail issues have to be dealt with, and test runs have to be performed before this part can go into production.

This design concerns a specific part of a remote control for an RC controlled vehicle that was originally manufactured in plastic but got broken.

And since the manufacturer doesn’t supply spare parts, the 3D printer came to the rescue …

The part was printed in Z-ULTRAT filament, and is currently successfully in use.